Home / Stabiliser AKS 3004 with spacers ø35/40/45mm and fixing bolts for braked trailers

drawbar ⌀35/40/45/50mm round, holes (screw connection) horizontal + cross 12.1mm, hole distance horizontal 47-54mm, cross 40mm, perm. gross weight 3000kg, nose load 150kg, material: cast iron. Read more...

| Drawbar tube ⌀ |

50mm |

| Holes (screw connection) | horizontal + cross 12,1mm |

| Hole distance | horizontal 47-54mm, cross 40mm |

| Perm. gross weight | 3000 kg |

| Nose load |

150 kg |

| D / Dc value |

26,9 kN |

| Material | Cast iron |

| Tightening torque strength class 8.8 | M12: 75 Nm |

| ECE type approval no. | E1 55R-01 0930 |

STABILISER COUPLING AKS™

for braked trailers up to 3000 kg

YOUR ADVANTAGE

Safe and relaxed driving with the AKS™

Swaying and pitching movements of the trailer are effec-tively suppressed with the stabiliser coupling.

Emergency situations

The vehicle combination can be restored to stability faster in an emergency situation with the AKS™. Furthermore, the stabiliser coupling permits a higher theoretical maximum speed (pay attention to permitted maximum speed). The AKS™ 3004/3504 complies with ISO 11555-1 (100 km/h approval possible).

Function

Operating the stabilisation handle presses four special friction pads against the car's towball from the left and right as well as the front and rear. The maximum braking torque of the pads can be 320 Nm. Swaying or pitching movements are thus effectively suppressed before they become serious.

Operation

The hitch and stabilisation handles are separate from one another, and each can be operated with one hand. No complicated additional securing devices. The stabilisation handle is simply opened for easier manoeuvring of the trailer.

The AKS – with even better ergonomics – has been presented with the Caravaning Design Award and the Red Dot Design Award for its particularly successful design!

On request as standard equipment or can be retrofitted to trailers with AL-KO chassis.

Function and operation

How to hitch up correctly:

- Use the hitch handle to place the AKS™ on the ball (ball must be free from grease and have a bare metal surface). Push the hitch handle down.

- Push the stabilisation handle down. The AKS™ is now ready for towing.

STABILISIERUNGSKUPPLUNG AKS™

für gebremste Anhänger bis 3.000 kg

YOUR ADVANTAGE

ECE approval – no TÜV registration is therefore necessary

Approved for 100 km/h operation accor-ding to ISO 1 1555-1

SURFACE TREATMENT

Housing: Dacromet-coated

Hitch handle: galvanised

Soft-Dock: rubber mixture

Stabilisation handle: Aluminium and Dacromet-coated, grip area additionally with plastic

CHECKING AND MAINTENANCE

| Safety indicator | Left/right friction pad wear indicator | Wear indicator |

| If the green cylinder is visible, the AKS™ is correctly mounted on the ball. | Friction linings are still OK. | Friction linings are worn. | Wear indicator for front/rear friction pads and hitch mechanism. |

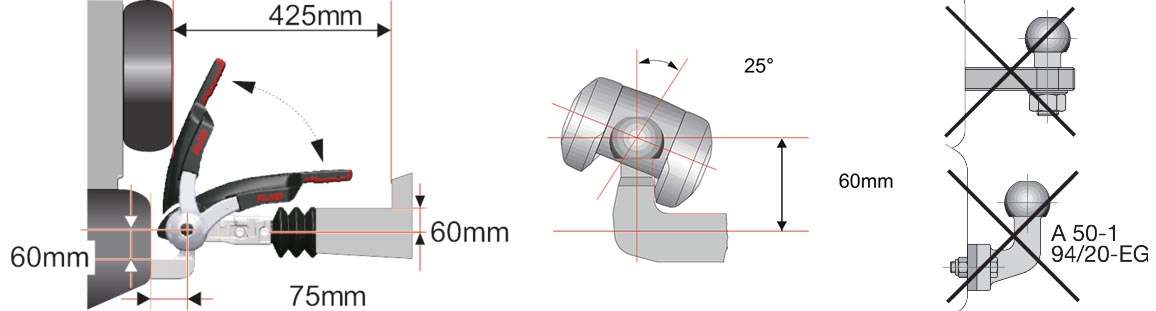

MOUNTING

Before mounting the AKS, check that the preconditions stated here have been met.

Please note: The ball head of the towing hitch must be free from grease and have a bare metal surface (paint must be removed).

Original operating instructions

Replacement part identification number (ETI) 811607

Here, you can find the catalogue page as a convenient PDF download.

You can also enter the part no. from the catalogue as a search term in our online store.